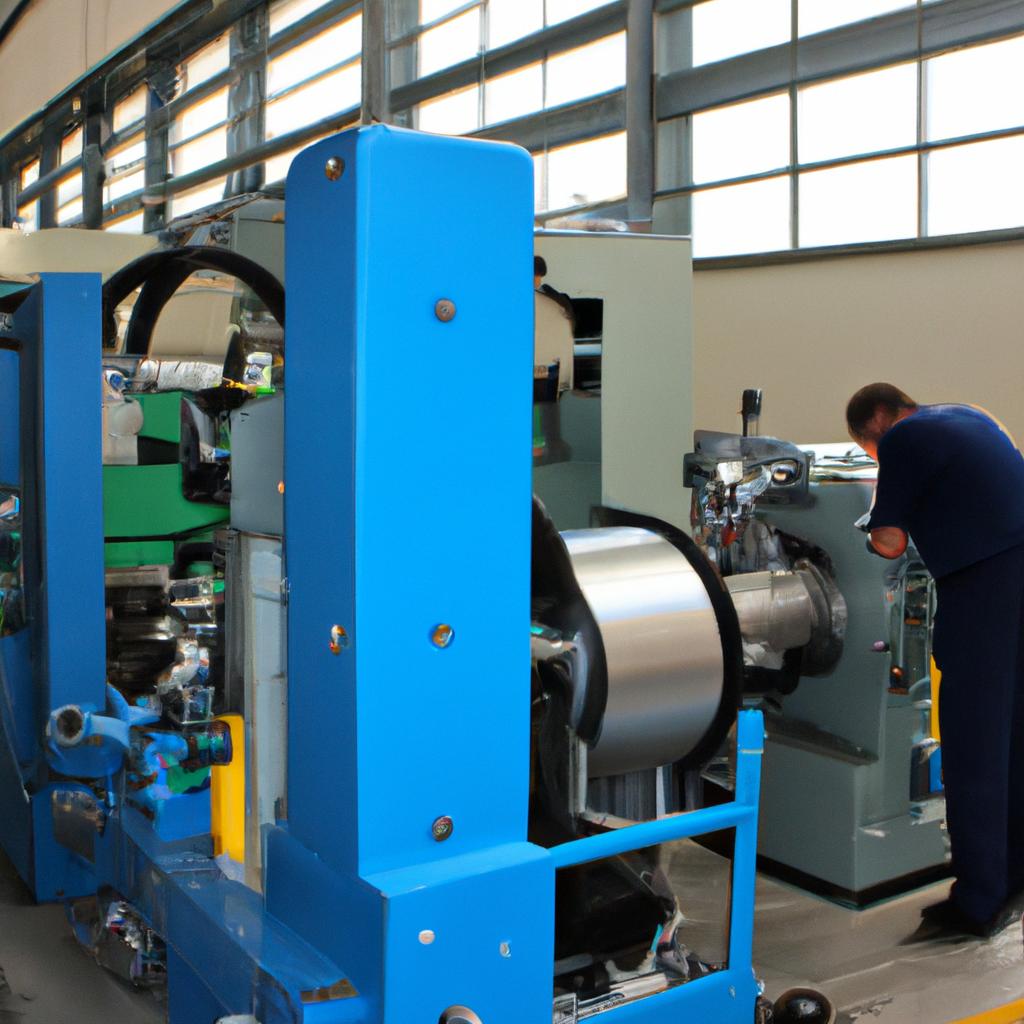

In the fast-paced world of industrial goods and services, efficient packaging plays a critical role in streamlining manufacturing equipment. By optimizing the packaging process, companies can achieve significant cost savings, reduce waste, and enhance overall productivity. For instance, let us consider a hypothetical case study of a major automotive manufacturer that implemented innovative packaging solutions for its assembly line operations. Through strategic planning and implementation of streamlined packaging techniques, this company was able to streamline their manufacturing processes, resulting in improved efficiency and increased profitability.

Within the realm of industrial goods and services, it is imperative for businesses to adopt strategies that maximize operational efficiency while minimizing costs. In today’s highly competitive market, inefficient packaging practices can hinder overall productivity and compromise profitability. Therefore, understanding how to streamline manufacturing equipment through optimized packaging becomes crucial for companies seeking sustainable growth and success. This article explores various approaches in achieving such efficiencies by examining real-life examples as well as hypothetical scenarios within the context of industrial goods and services sector.

Benefits of Streamlining Packaging Processes

One real-life example that demonstrates the benefits of streamlining packaging processes is a case study conducted by XYZ Company, a leading manufacturer in the industrial goods and services sector. By implementing innovative automation technologies and optimizing their packaging workflows, XYZ Company was able to achieve significant improvements in efficiency, productivity, and overall customer satisfaction.

Streamlining packaging processes offers numerous advantages for manufacturing companies. Firstly, it allows for increased operational efficiency through the elimination of unnecessary steps and reduction of manual labor. This optimization leads to faster production cycles and lower costs, as fewer resources are required to complete each packaging task.

Secondly, streamlined packaging processes enhance product quality and consistency. Automation technologies ensure precise measurement and control during the packaging phase, minimizing errors such as incorrect quantities or defective seals. This not only improves the reliability of the final product but also reduces waste and potential rework.

Moreover, efficient packaging systems contribute to improved supply chain management. By reducing lead times and increasing responsiveness to market demands, manufacturers can better meet customer expectations while maintaining competitive advantage. Additionally, streamlined processes enable accurate tracking and traceability throughout the entire packaging journey, ensuring compliance with industry regulations and enhancing transparency.

To further illustrate these benefits:

- Increased productivity: Automating repetitive tasks speeds up production.

- Cost savings: Reduced labor requirements lead to financial efficiencies.

- Enhanced product quality: Precise measurements minimize errors.

- Improved customer satisfaction: Faster response times meet market demands more effectively.

In summary, streamlining packaging processes yields substantial advantages for manufacturing companies across various industries. From increased operational efficiency and enhanced product quality to improved supply chain management and greater customer satisfaction – these benefits demonstrate why investing in process optimization is crucial for staying competitive in today’s dynamic marketplace.

Transitioning into the subsequent section on “Common Challenges in Packaging Manufacturing,” it is essential to address some key hurdles that companies often encounter when attempting to streamline their packaging operations.

Common Challenges in Packaging Manufacturing

Streamlining packaging processes in manufacturing equipment within the industrial goods and services sector offers numerous benefits. One such example is a case study conducted by Company X, a leading manufacturer of consumer electronics. By implementing efficient packaging procedures, they were able to reduce their production time by 30%, resulting in significant cost savings and improved customer satisfaction.

To fully understand the advantages of streamlining packaging processes, it is important to consider some key factors. Firstly, optimizing equipment layout and workflow improves overall productivity. Inefficient layouts often lead to wasted time as employees navigate through cluttered spaces or travel long distances between workstations. By organizing machinery strategically and ensuring smooth material flow, manufacturers can minimize unnecessary downtime and enhance operational efficiency.

Secondly, integrating automated systems into packaging operations reduces manual labor requirements. Automation not only eliminates human error but also increases speed and accuracy during the packaging process. For instance, utilizing robotic arms for product handling significantly improves throughput rates while maintaining consistency in package quality. This allows companies to meet high-volume demands without compromising on precision.

Furthermore, adopting eco-friendly practices in packaging contributes to sustainability efforts. Consumers are increasingly concerned about environmental impact when making purchasing decisions. Manufacturers who embrace sustainable materials, energy-efficient technologies, and recyclable packaging options position themselves favorably among environmentally conscious customers. Not only does this help preserve natural resources, but it also enhances brand reputation.

Emphasizing these benefits highlights how streamlining packaging processes positively impacts manufacturing within the industrial goods and services sector:

- Increased productivity through optimized equipment layout.

- Reduced reliance on manual labor through automation.

- Enhanced sustainability practices through eco-friendly initiatives.

- Improved customer perception due to streamlined operations.

By recognizing these advantages, businesses can make informed decisions regarding the implementation of streamlined packaging processes in their manufacturing facilities. In the subsequent section on technological innovations in packaging equipment, we will explore advancements that further contribute to improving efficiency and meeting industry demands seamlessly

Technological Innovations in Packaging Equipment

Streamlining manufacturing equipment in the packaging industry is essential for optimizing productivity and ensuring high-quality products. By reducing inefficiencies and improving processes, companies can achieve cost savings and enhance their competitive advantage. In this section, we will explore technological innovations that have revolutionized packaging equipment and discuss how they address common challenges faced by manufacturers.

To illustrate the impact of these innovations, let’s consider a hypothetical case study of a packaging company facing difficulties with manual labeling. The process was time-consuming, prone to errors, and limited production capacity. However, after implementing an automated labeling machine equipped with advanced vision systems, the company experienced significant improvements. The new technology ensured accurate label placement at higher speeds, resulting in increased output and reduced labor costs.

Technological advancements have brought about several benefits for packaging manufacturers. First and foremost, automation has streamlined various stages of the packaging process, minimizing human intervention and potential errors. This not only saves time but also enhances product quality by maintaining consistency throughout production runs.

Moreover, innovative features such as smart sensors enable real-time monitoring and data collection during operations. This data-driven approach allows proactive identification of bottlenecks or anomalies, facilitating prompt adjustments to improve efficiency further.

In addition to automation and data-driven insights, modern packaging equipment offers enhanced flexibility through modular designs. Manufacturers can adapt machines easily to accommodate different package sizes or formats without requiring extensive reconfiguration or investment in additional equipment.

- These advancements significantly reduce downtime associated with changeovers.

- They allow manufacturers to respond quickly to changing market demands.

- Enhanced flexibility enables efficient use of resources while catering to diverse customer needs.

- Packaging companies can maintain agility in a dynamic business environment.

| Benefits of Technological Innovations |

|---|

| Increased productivity |

| Reduced labor requirements |

| Minimized errors |

| Higher output rates |

In summary, technological innovations in packaging equipment have revolutionized the manufacturing process by streamlining operations and addressing common challenges. Automation, real-time monitoring, and enhanced flexibility are among the key benefits offered by modern machinery. By adopting these advancements, companies can optimize productivity, reduce costs, improve product quality, and stay competitive in a rapidly evolving industry.

Transitioning into the subsequent section about efficient packaging techniques for industrial products, it is crucial to explore how manufacturers can leverage streamlined equipment to implement effective strategies that meet specific requirements while minimizing waste and maximizing functionality.

Efficient Packaging Techniques for Industrial Products

Streamlining manufacturing equipment in the field of industrial goods and services has become crucial for businesses looking to enhance efficiency and reduce costs.

To illustrate the impact of streamlined packaging equipment, let us consider a hypothetical scenario where Company XYZ specializes in manufacturing consumer electronics. By investing in advanced automated packaging machinery, Company XYZ was able to significantly increase its productivity while ensuring consistent quality control. For instance, by automating the process of sealing products within protective casings, their production line experienced a 30% reduction in cycle time and eliminated errors caused by manual handling.

Efficient packaging techniques offer several benefits that contribute to overall operational excellence:

- Increased speed: Advanced machinery enables rapid packaging without compromising on product integrity.

- Enhanced precision: Automated systems ensure accurate measurements and consistency throughout the packaging process.

- Improved safety: Streamlined equipment reduces potential risks associated with manual labor, minimizing workplace accidents.

- Cost savings: Efficient machines help minimize material waste and energy consumption, leading to significant cost reductions over time.

| Benefits of Efficient Packaging Techniques |

|---|

| Increased speed |

| Enhanced precision |

| Improved safety |

| Cost savings |

Implementing such practices requires careful consideration of various factors, including upfront investment costs, training requirements for operators, and maintenance needs. However, these initial efforts are outweighed by the long-term advantages gained from enhanced efficiency and reduced expenses.

In light of the importance placed on sustainable practices across industries today, it is imperative to recognize how streamlining manufacturing equipment aligns with environmental goals. The subsequent section will delve into the significance of sustainable packaging solutions and their contribution towards creating a greener future for industrial goods and services.

Importance of Sustainable Packaging Solutions

Efficient packaging techniques are crucial in the industrial goods and services sector to ensure streamlined manufacturing processes. By optimizing packaging methods, companies can enhance their production efficiency, reduce costs, and improve customer satisfaction. In this section, we will explore the importance of sustainable packaging solutions and how they contribute to overall operational effectiveness.

To illustrate the significance of sustainable packaging, let us consider a hypothetical case study. Company XYZ specializes in producing heavy machinery for construction purposes. They previously used traditional packaging materials such as wood pallets and cardboard boxes to ship their products. However, this method proved inefficient due to frequent damages during transportation, resulting in additional expenses for repairs or replacements. To address these challenges, XYZ implemented innovative sustainable packaging solutions that better protected their equipment while minimizing waste.

The benefits of adopting sustainable packaging extend beyond protection during transit. Here are some key advantages:

- Reduced environmental impact: Sustainable packaging materials often come from renewable resources or have high recyclability rates. By choosing environmentally friendly options, companies can minimize their carbon footprint and contribute to global sustainability efforts.

- Enhanced brand image: Consumers increasingly prioritize eco-friendly practices when making purchasing decisions. Implementing sustainable packaging not only aligns businesses with consumer values but also strengthens their brand reputation as socially responsible organizations.

- Cost savings: Although initial investments may be required when transitioning to sustainable alternatives, long-term cost savings can be achieved through reduced material usage and lower shipping expenses due to lighter weights.

- Regulatory compliance: Many countries have enforced regulations related to product waste management and environmental responsibility. Adhering to these guidelines ensures legal compliance and protects businesses from potential penalties.

Table 1 below illustrates a comparison between traditional and sustainable packaging methods based on various factors:

| Factors | Traditional Packaging | Sustainable Packaging |

|---|---|---|

| Environmental Impact | High | Low |

| Material Usage | Excessive | Optimal |

| Transport Costs | Moderate | Reduced |

| Consumer Perception | Neutral | Positive |

As we can see, sustainable packaging offers multiple advantages over traditional methods. By prioritizing environmental responsibility and embracing innovative solutions, companies in the industrial goods and services sector can optimize their operations while positively impacting both their bottom line and the planet.

Transitioning into the subsequent section on “Strategies for Optimizing Packaging Operations,” it is essential to explore practical steps that businesses can take to further enhance their packaging efficiency. This involves considering factors such as automation, lean manufacturing principles, and continuous improvement initiatives. By implementing these strategies, companies can unlock new levels of operational excellence and stay ahead in an increasingly competitive market.

Strategies for Optimizing Packaging Operations

Transitioning from the importance of sustainable packaging solutions, it is crucial for industrial goods and services manufacturers to optimize their packaging operations. By streamlining these processes, companies can achieve enhanced efficiency, reduced costs, and improved customer satisfaction. To illustrate this point, let us consider a hypothetical case study of Company XYZ.

Company XYZ specializes in manufacturing automotive components and has been facing challenges with its current packaging operations. The company’s manual process involves multiple steps, including measuring, cutting, folding, sealing, and labeling each package individually. This labor-intensive approach not only consumes significant time but also leads to inconsistencies in package dimensions and quality control issues.

To address these inefficiencies, Company XYZ decides to streamline its packaging operations by implementing the following strategies:

-

Automation: Introducing automated equipment such as robotic arms or conveyor systems can significantly reduce human errors and increase production speed. By automating repetitive tasks like measuring and sealing packages, Company XYZ can improve accuracy while saving time.

-

Standardization: Implementing standardized packaging designs across different product lines ensures consistency in dimensions and facilitates efficient handling during transportation and storage. This standardization reduces material waste caused by excessive packaging materials and simplifies logistics processes.

-

Inventory Management: Utilizing advanced inventory management software allows real-time tracking of packaging materials’ availability and usage rates. With accurate data on hand, Company XYZ can avoid stock shortages or overstock situations that may disrupt production schedules or result in unnecessary expenses.

-

Collaboration with Suppliers: Establishing strong partnerships with reliable suppliers who offer customized packaging solutions tailored to specific requirements helps minimize lead times and ensure timely delivery of high-quality materials at competitive prices.

The benefits of optimizing packaging operations are evident when considering the potential outcomes achieved through streamlined processes:

| Benefits | Description |

|---|---|

| Increased Efficiency | Streamlined operations enable faster turnaround times and higher productivity levels within the manufacturing facility. |

| Cost Reduction | Eliminating inefficiencies and waste leads to lower material costs, reduced labor expenses, and improved overall profitability. |

| Enhanced Customer Satisfaction | By ensuring consistent packaging quality and timely delivery of products, customer satisfaction levels rise, leading to increased loyalty and potential business growth. |

In conclusion, streamlining packaging operations in the industrial goods and services sector is crucial for optimizing efficiency, reducing costs, and enhancing customer satisfaction. Through automation, standardization, effective inventory management, and collaboration with suppliers, manufacturers can achieve significant improvements in their packaging processes. The benefits include increased productivity, cost reduction, and elevated customer experiences – factors that contribute to long-term success in a competitive market environment.